What is Optimisation

Optimisation, or mathematical optimisation, is the selection of a best element (with regard to some criterion) from some set of available alternatives. It can be used to define real-world problems in mathematical functions, that can be minimized or maximized to find the most optimal solution. In the context of equipment management, it can be used to model options for flowing empty containers and producing a flow plan, minimized to the overall cost.

In a collaboration between Equipment and Network Strategy in the business, a system "DDFO" (Data Driven Flow Optimisation) is built to facilitate all the work involved with defining, running and solving optimisation problems for empty flow, in a highly configured software (i.e. a "solver"). As the optimisation model is able to process a very large set of criteria and options, it can easily outperform humans in their planning ability, given inputs and constraints are correct. To support frequent and high-quality inputs to the solver, the application ROCK (used by equipment planners) and the DDFO system (containing the solver) are highly integrated with each other.

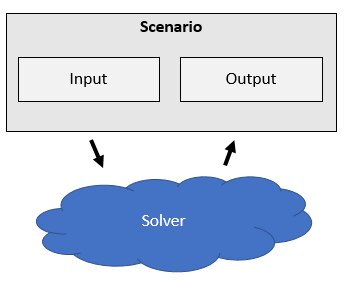

To correctly capture optimisation problems for the solver, relevant data is collected and managed as a "Scenario", consisting of multiple data inputs (e.g. network, current stock, ROFO empty forecast etc.), and the data outputs of the solver, i.e. the result.

Data-driven Flow Optimisation

DDFO consists of two solvers to handle two different optimisation problems, balancing the target stock levels with the forecasted empty demand of containers.

The Regional Equipment Plan (REP) is a long-term empty flow plan based on the long-term commercial demand of empty containers. The demand is calculated by determining the expected bookings from ROFO, and translating it into empty demand, through a complex logic, based on average patterns on turn-times for export pick-up and import returns (i.e. The ROFO Imbalance Forecast). By using ROFO, the equipment flow plan is able to comply with long-term regional trends and goals set by the commercial organisation.

The Port Level Plan (PLP) is a short-term empty flow plan based on the Auto Forecast, produced weekly by Maersk Digital. In contrast to ROFO, the Auto Forecast is is calculated in more detailed geo levels (pool instead of flow area), for more refined equipment types and per operator in Maersk Liner Business.

By having a long-term plan with REP and a short-term plan with PLP, it is possible to make short-term decisions that comply with the long-term goals of the organisation (e.g. building up stock for Chinese new year). Below table summarizes the main differences between the two plans.

| REP | PLP | |

|---|---|---|

| Main purpose | Identify long-term trends and comply with commercial ROFO | Best-use of network to comply with short-term and long-term demand |

| Geo-Level of Flow Targets | Flow Area | Site |

| Flow Targets Granularity | Monthly flows per service | Specific sailings |

| Imbalance Forecast | Based on ROFO, forecast is translated into long-term empty demand (12 months) | Auto Forecast to (8 weeks) |

| Target Stock | Projected Stock Level (12 months) | Target Stock Level (8 weeks) |

| Plan Release Frequency | Monthly | Daily |

Scenario Management

REP and PLP are both created and managed in ROCK using scenarios. By using the scenarios, it is possible to create a specific plan to be considered the effective target for a given period (i.e. the "basecase"). It is also possible to use scenarios to experiment and simulate different inputs (e.g. cost, network, target stock levels etc.) to see how different changes will impacts the plan.

To manage scenarios and ensure ROCK always has a valid basecase, the two screens "REP Scenario Manager" and "PLP Scenario Manager" are used.